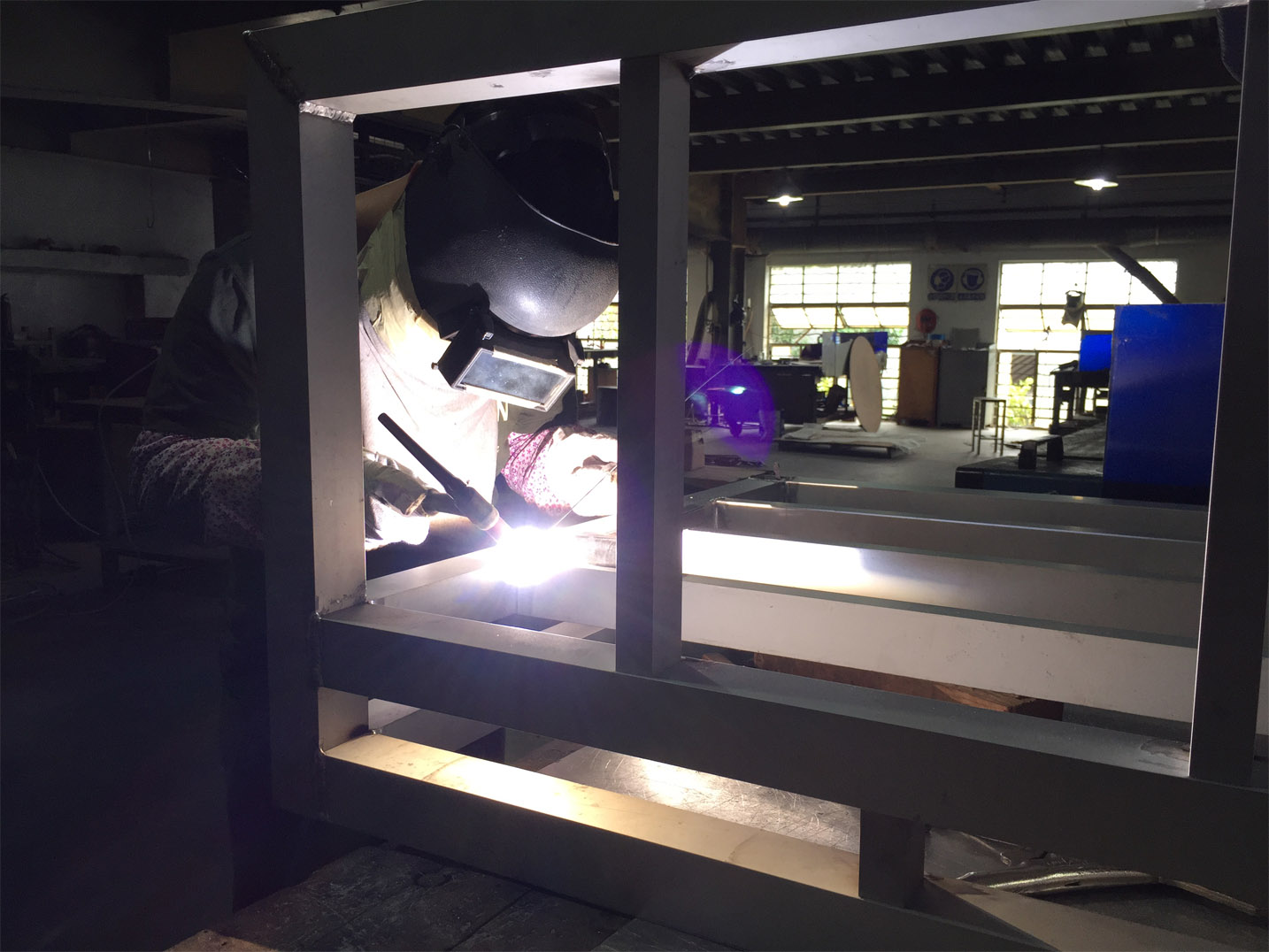

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

One of the most common types of arc welding is shielded metal arc welding (SMAW); it is also known as manual metal arc welding (MMAW) or stick welding. Electric current is used to strike an arc between the base material and consumable electrode rod, which is made of filler material (typically steel) and is covered with a flux that protects the weld area from oxidation and contamination by producing carbon dioxide (CO2) gas during the welding process.

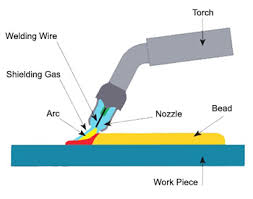

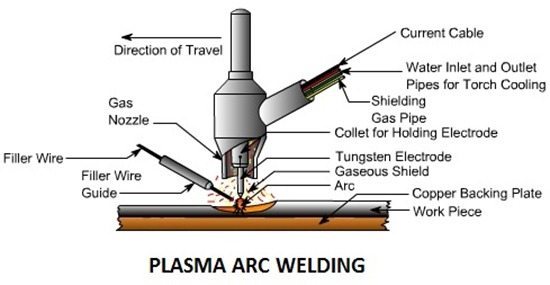

This category includes a number of common manual, semi-automatic and automatic processes. These include metal inert gas (MIG) welding, stick welding, tungsten inert gas (TIG) welding also know as gas tungsten arc welding (GTAW), gas welding, metal active gas (MAG) welding, flux cored arc welding (FCAW), gas metal arc welding (GMAW), submerged arc welding (SAW), shielded metal arc welding (SMAW) and plasma arc welding.

These techniques usually use a filler material and are primarily used for joining metals including stainless steel, aluminium, nickel and copper alloys, cobalt and titanium. Arc welding processes are widely used across industries such as oil and gas, power, aerospace, automotive, and more.