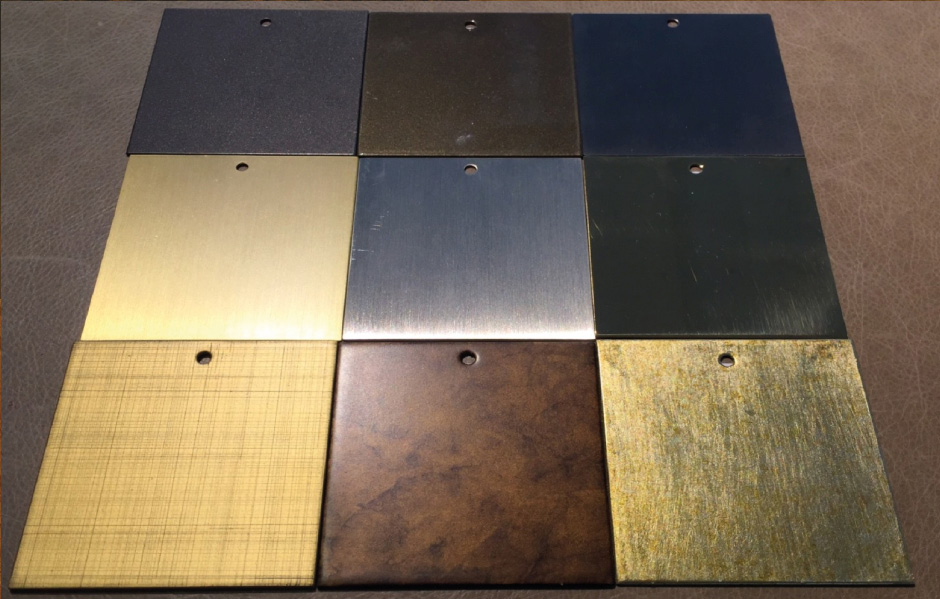

The types of metals we use mostly are steel, brass, aluminium and stainless steel. From these base metals we are able to create a wide variety of finishes. Our popular standard finishes are ‘Burnished Bronze’ and ‘Antique Silver Leaf’, but there are plenty more.

Popular standard metal finishes from the Decca Home brands

Popular standard metal finishes from the Decca Home brands

To make the burnished bronze finish the brass is brushed and then painted. We can achieve a very light or very dark colour using this method, and we have a set of samples illustrating this in our showroom. We can also oxidise the brass to give a very matt tarnished look which works particularly well on a more intricate silhouette.

Brass finishes including our burnished bronze, and oxidised brass

Brass finishes including our burnished bronze, and oxidised brass

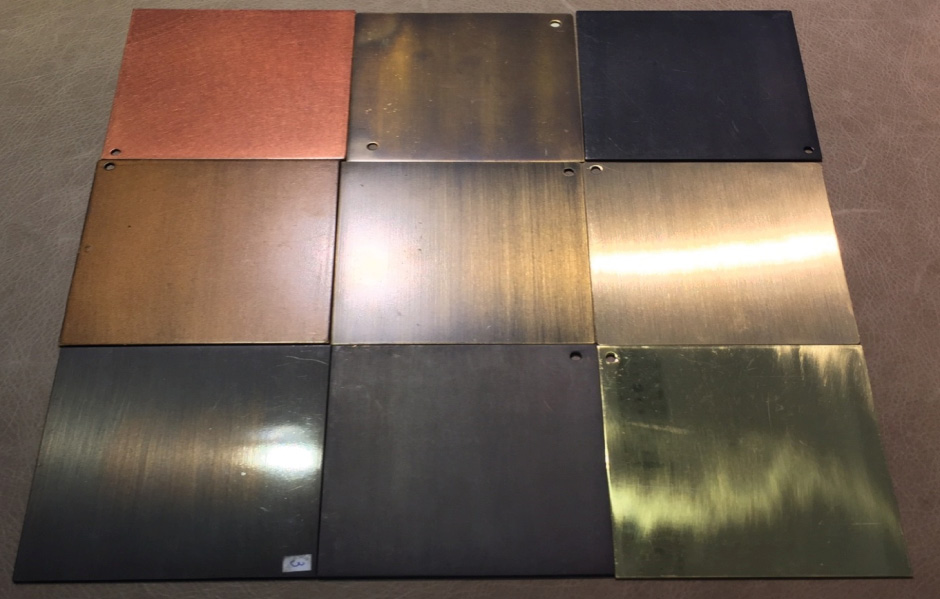

PVD coating is a relatively new finish that we offer. There are a number of interesting colours offered in mirror (polished) and hairline (brushed) options. The stainless steel is polished and then coated. This allows for a finish that resembles brass/bronze/nickel and combines the strength of steel. This has a practical application for creating a weight bearing frame or leg, which brass, being a soft metal, would not allow. Also, from a cost perspective, the polished stainless steel is less than the cost of brass. Much of the metal work in our ‘Cosmopolitan Collection’ by Dakota Jackson uses this new technique with brilliant effect.

The collection can be seen here:

A selection of PVD coated stainless steel in a variety of colours

A selection of PVD coated stainless steel in a variety of colours

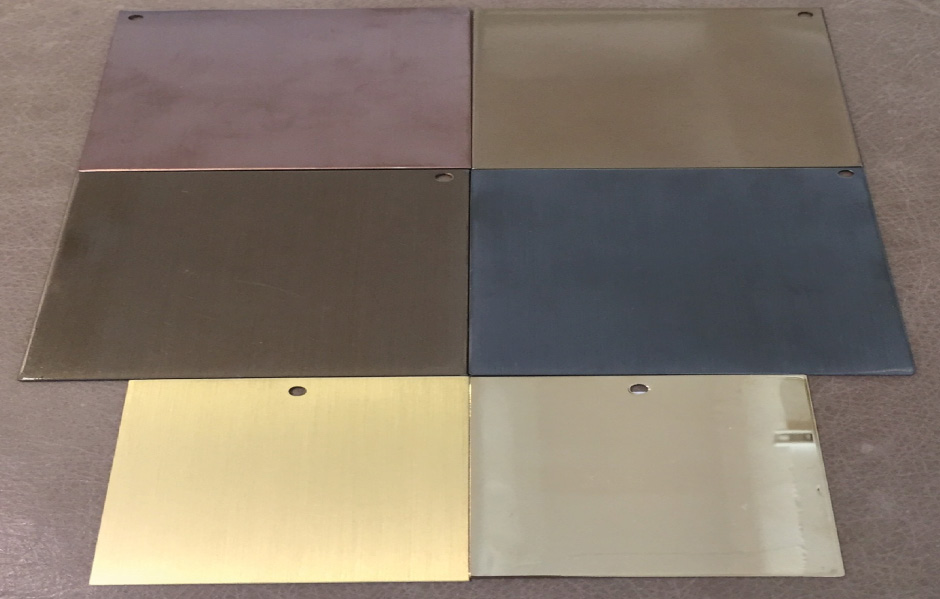

Our silver and gold leaf is applied to a cleaned steel frame, and then there are options for applying a degree of antiquing or distressing. Our antique silver leaf for instance has a slightly yellow varnish applied which mellows the bright silver and gives a very light golden appearance.

Silver leaf in various antiqued applications

Silver leaf in various antiqued applications

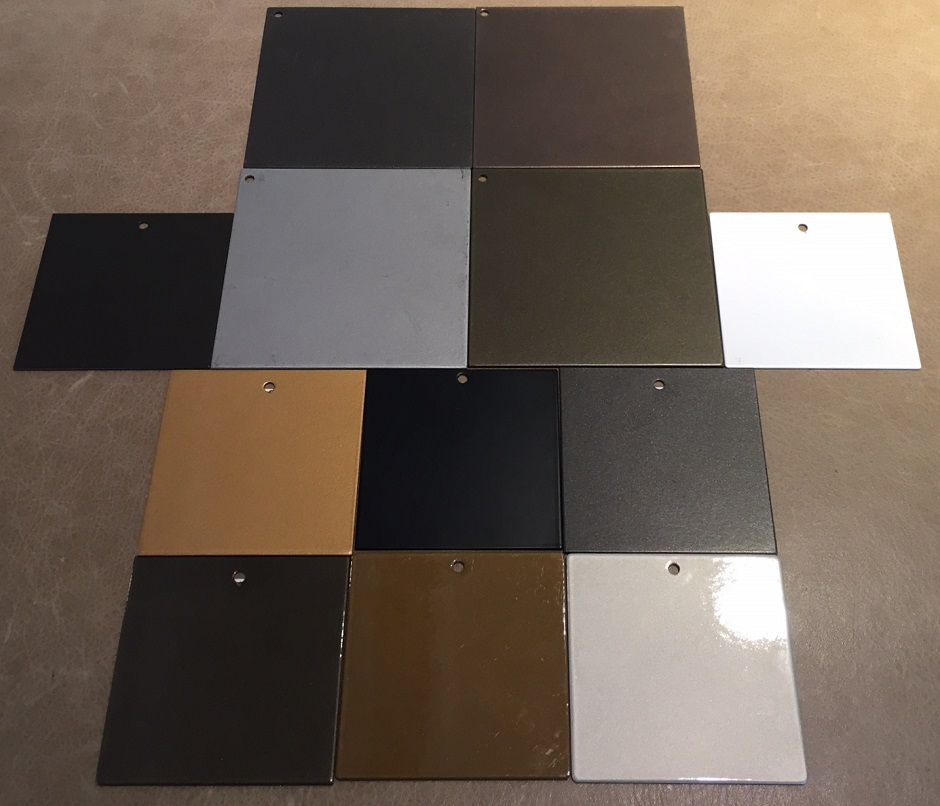

We also offer a powder-coat finish. This is applied to cleaned steel or aluminium frames and offers a durable finish that can be gloss or matt. We have a variety of standard powder-coat finishes including white, black, bronze, taupe, silver and gun metal.

A selection of powder coat colours available in various sheen levels

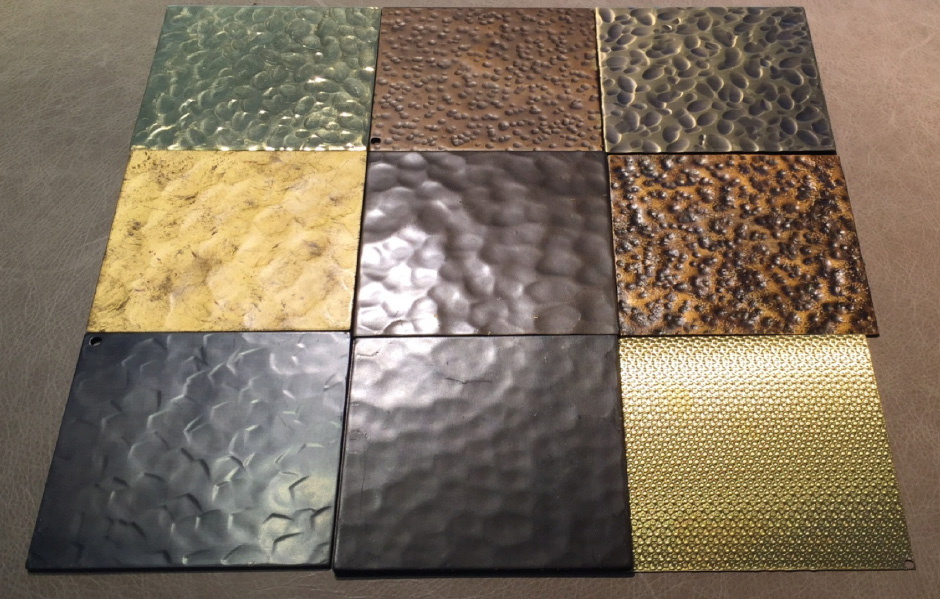

We can create a number of textures to the metal finish, with the most popular being a hammered bronze.

Textured metal finishes

Textured metal finishes

The practical applications of our metals can be seen in many of our standard products, such as inlay bands, table frames etc., but also in many bespoke pieces we produce. We designed and created our showroom workbench using a laser-cut metal base and applying a brushed PVD bronze coat which is then painted to give the burnished bronze look and feel. Other metal finishes such as, brushed brass, PVD mirror gold, bronze powder coat, antiqued silver leaf and hammered brass are also on display in the showroom.

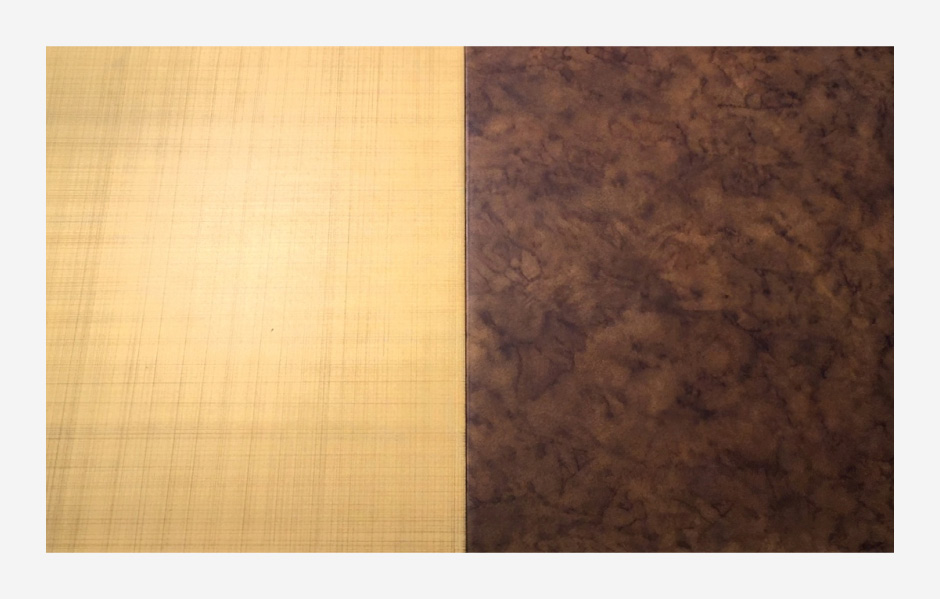

The designers we work with are constantly creating new finishes with an understanding of what’s possible. Michael Kirkpatrick, the creator of our new Objet collection, has worked with us to produce some particularly interesting finishes. These include two metal finishes shown below, notably, a cross-hatch gold painted steel and a faux antique brass. The gold paint is applied to an already black powder-coated steel and then etched by hand. The faux antique brass is actually a steel metal, where hand painting techniques are applied onto a powder-coated base layer.  Metal finishes from the new ‘Objet Collection’ by Michael Kirkpatrick

Metal finishes from the new ‘Objet Collection’ by Michael Kirkpatrick

We are very happy to explore new metal finishes with clients to create something unique, and enjoy the challenge of trying to produce new and beautiful metal pieces. The standard metal finishes and our extensive set of bespoke metal finishes in the showroom library help illustrate the differences between techniques and are well worth looking through to see what can be achieved.

2 September 2015