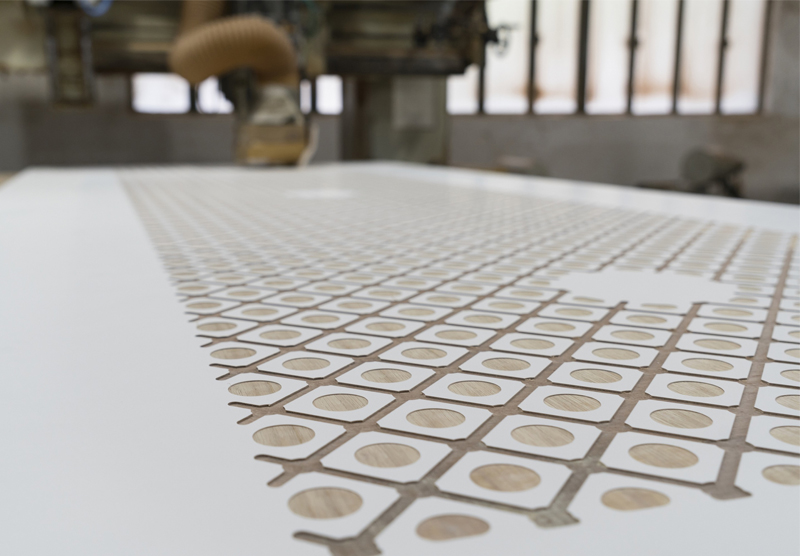

Computer Numerical Control is the automated control of machining tools and 3D printers by means of a computer. A CNC machine processes a piece of material to meet specifications by following a coded programmed instruction and without a manual operator directly controlling the machining operation.

When a CNC system is activated, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks as specified, much like a robot. In CNC programming, the code generator within the numerical system will often assume mechanisms are flawless, despite the possibility of errors, which is greater whenever a CNC machine is directed to cut in more than one direction simultaneously.

|

|

In CNC, machines are operated via numerical control, wherein a software program is designated to control an object. The language behind CNC machining is alternately referred to as G-code, and it’s written to control the various behaviours of a corresponding machine, such as the speed, feed rate and coordination.

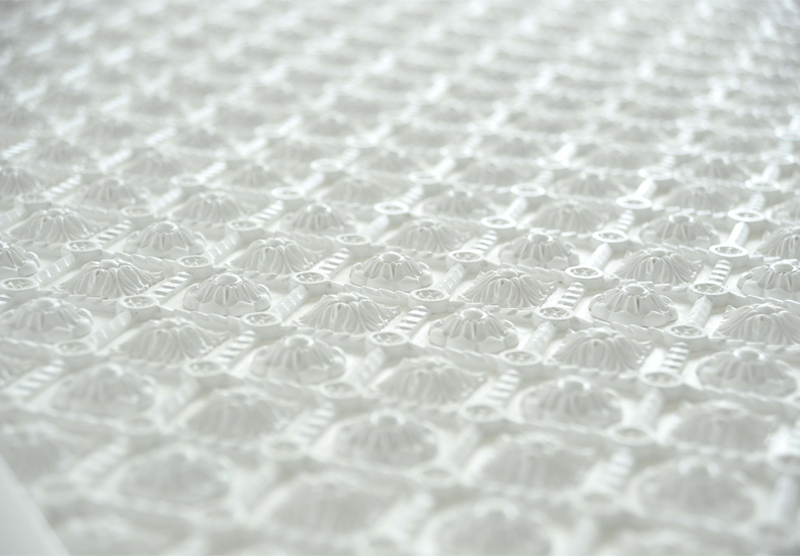

Basically, CNC machining makes it possible to pre-program the speed and position of machine tool functions and run them via software in repetitive, predictable cycles, all with little involvement from human operators. Due to these capabilities, the process has been adopted across all corners of the manufacturing sector and is especially vital in the areas of metal and plastic production.

The system is used to make highly detailed cuts out of metal pieces for industrial hardware products. In addition to the aforementioned machines, further tools and components used within CNC systems include: