We will quote fabric required based on a width of 137cm and a repeat up to 4cm. If your fabric is significantly narrower or wider we can re quote. If the pattern repeat is larger we may need a large fabric sample to work out placement and so total quantity required.

Leather is quoted in square foot (sq/ft), we assume a hide size of 50 to 55 sq/ft. so again let us know if the hide size is significantly different.

We always quote the amount of material or leather required per item, and is written as COM (Customers Own Material) or COL (Customers Own Fabric). We do not have our own fabric or leather range but can help in particular circumstances.

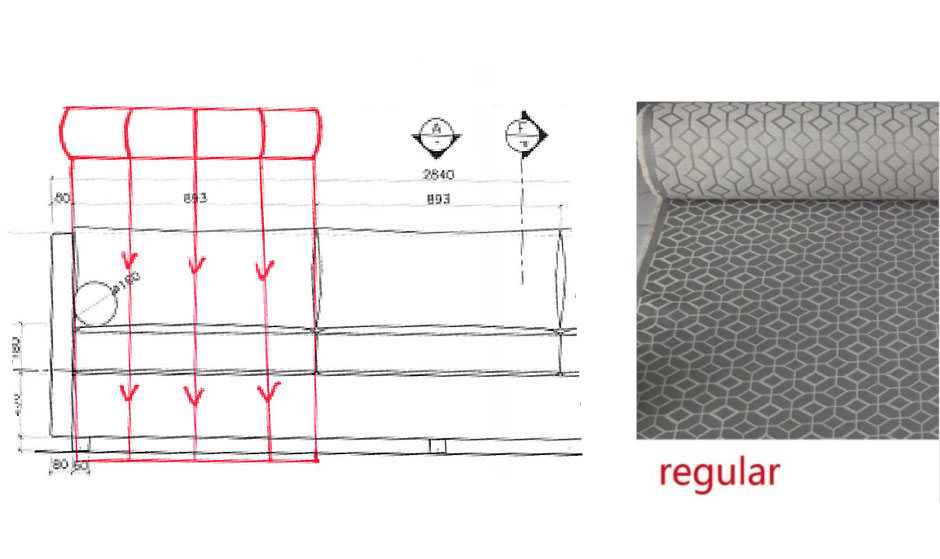

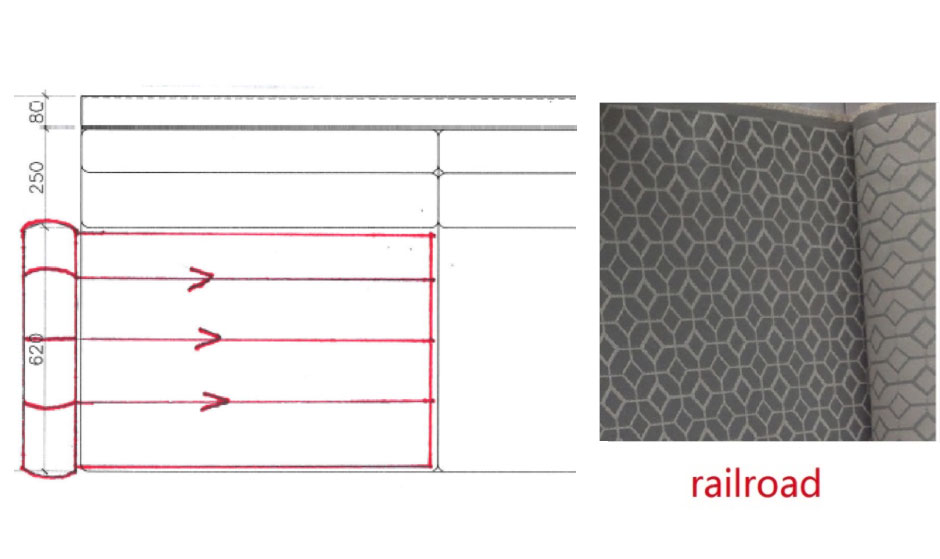

Fabric Direction:

We will assume “regular” upholstery use unless otherwise specified.

Regular upholstery direction is vertically applied to a piece. This can cause seam lines due to the width constraint of 1370mm. (See below images)

Railroad upholstery direction is horizontally applied onto an item. (See below images)

Our factory is very experienced at placement of designs on upholstery, however if you have specific requirements we suggest you give us a drawing so that we can easily communicate your request.

Use of several fabrics on one ite

Use of several fabrics on one iteIf you are using different fabrics on one item then the simplest way is to highlight in different colours on the shop drawing which fabric, where. We will then get our upholsterers to re quote COM or COL for each for you.

We can mix leather and fabric, and of course self-pipe or contrast pipe.

FR Interliner is used by our factory on all residential projects (and is priced in to the project automatically). Therefore you can use fabrics in natural fibre that pass the cigarette test. It is not necessary for these to pass the Match test.

For commercial projects in either a hospitality or contract environment, Crib 5 treatment is required to pass the UK regulations, and we will require an FR certificate. Use of an interliner is not sufficient for these areas.

Our factory use certified CMHR foam and dacron which passes BS5852. If you require certificates for this please just ask a member of our team.

As we do not know the specific requirements of your project we do not make judgements on your fabric durability. However some silks and satin weave fabrics can show all needle marks and so we will use them at your risk only. For durability it is recommended you look at both rub test results and wing rip and tear test.

We do not have stain repellent treatment capabilities once the item is complete, so if this is required we suggest this is done in the UK on the fabric before it is sent to Decca.

The Decca factory requires all material or leather six weeks before the ship out date in order to complete the project on time. For hospitality projects or if you are short of time we expect you to send fabric direct to our office in Hong Kong, we can send you a fabric label from so that it is quickly identified. For all smaller projects we can send the fabric to them for you, so deliver it to our London office with all the project and item details on it.

6 September 2015