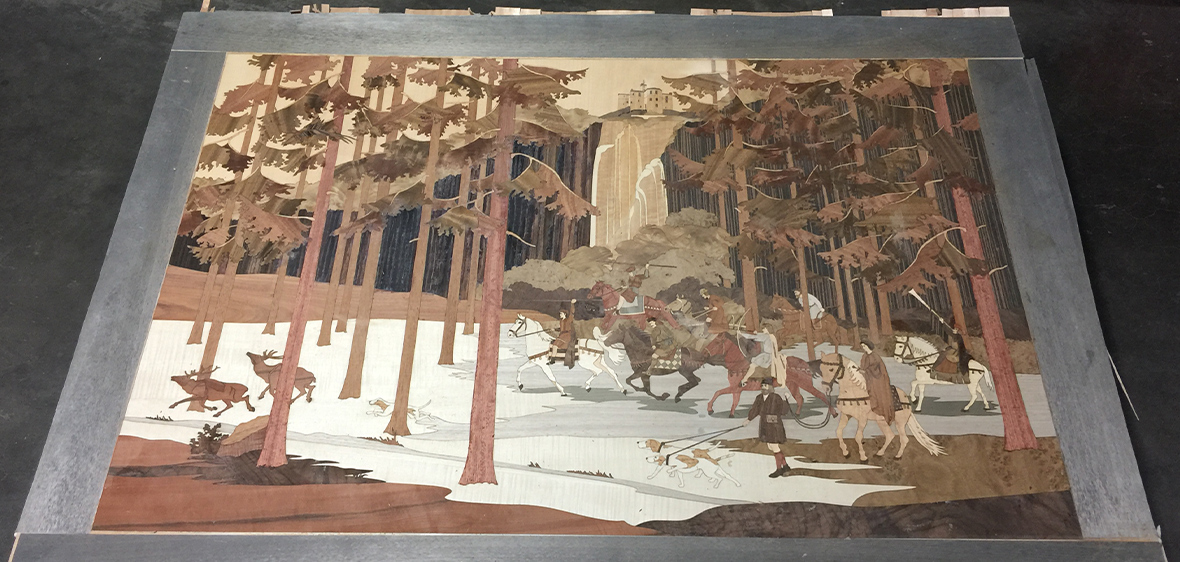

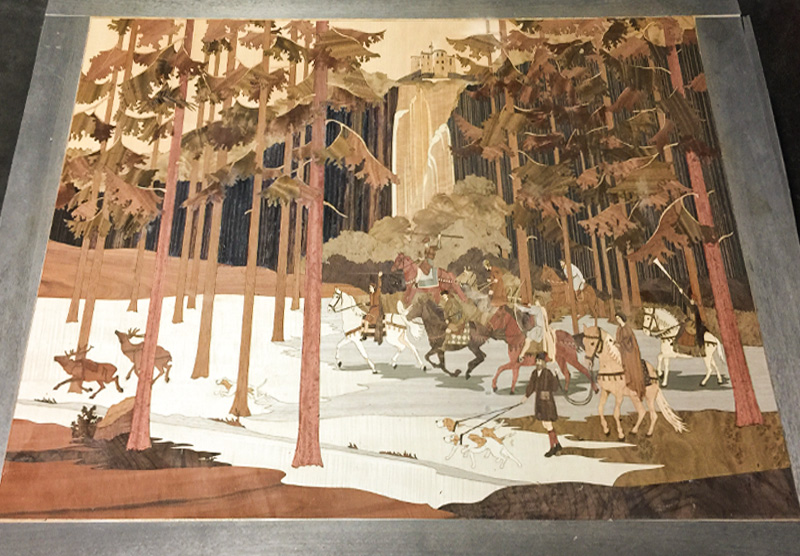

Marquetry is the art of creating designs and pictures out of carefully fitted pieces of thin wood. Using precisely cut pieces that fit together perfectly, craftspeople create elaborate designs and pictures using only the wide variety of colours and grains that exist in different wood species.

Because of its complexity and delicacy, marquetry had to be done by hand for centuries. Pieces of wood were carefully cut out using small jigsaws, then carved or sanded to fit together. In the modern era, laser techniques have been developed that drastically reduce the amount of time required to make a marquetry furniture. Decca still carries this tradition on till this day with the help of our talented craftsmen and craftswomen.

The veneers used are primarily woods, but may include bone, ivory, turtle-shell, mother-of-pearl, pewter, brass or fine metals. Marquetry using colored straw was a specialty of some European spa resorts from the end of the 18th century. Many exotic woods as well as common European varieties can be employed, from the near-white of boxwood to the near-black of ebony, with veneers that retain stains well, like sycamore, dyed to provide colors not found in nature.

|

|

Marquetry as a modern craft most commonly uses knife-cut veneers. However, the knife-cutting technique usually requires a lot of time. For that reason, many marquetarians have switched to fret or scroll saw techniques. Other requirements are a pattern of some kind, some brown gummed tape (IE as the moistened glue dries it causes the tape to shrink and so the veneer pieces are pulled closer together), PVA glue and a base-board with balancing veneers on the alternate face to compensate stresses.

The marquetry artist, or marquetarian, selects the veneers based on the right combination of grain, color, and texture needed to create the desired artistic impression. Next, a pattern is chosen and the individual veneer pieces that will make up the design or picture are cut out using either a knife or a fret saw. Following this, the pieces are glued together and the completed design is mounted onto a rigid base and sanded flat.

Finally, a finish is applied to protect the wood and the marquetry piece is completed. The infinite variety of veneers, grain, and figuration insures a unique one-of-a-kind product every time.